Rail-Master DJ-A

Laser Calibrator Guide Rail Installation

General information

DJ-A series Guide Rail Installation Laser Calibrator (Call instrument as follows) is a portable fine measuring instrument, provide a new method with high precision for the installation and co-planarity inspection of guide rails. It is a very useful tool for elevator installation, maintenance and inspection. Easy to operate and raise your working efficiency.

Its characteristic is to provide one laser beam which is parallel with datum face of Guide Rail, replace traditional method. This instrument is easy to operate, save time, labor-saving, raise the working efficiency. The high accuracy ensures the quality of installation. It is a portable instrument with light weight, the right-hand tool for elevator installation, rebuilt and testing.

Structure

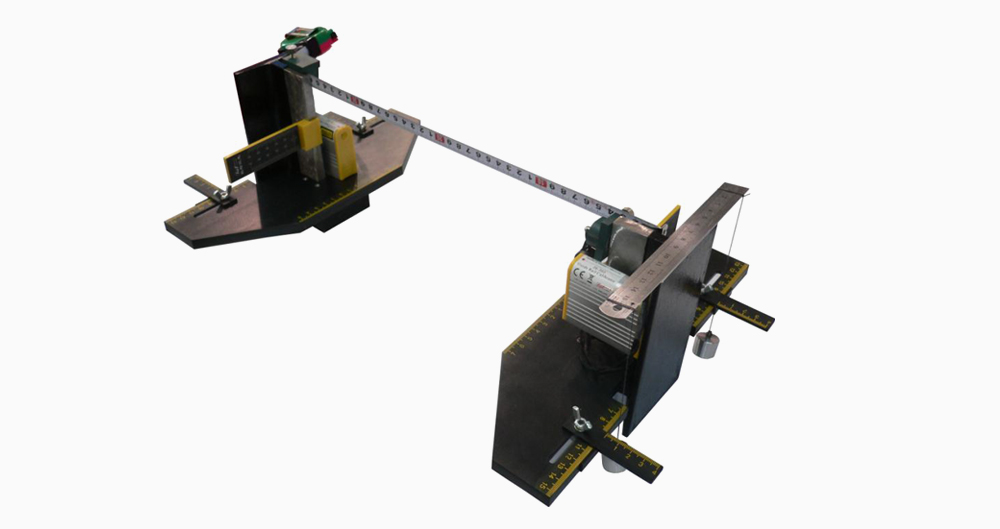

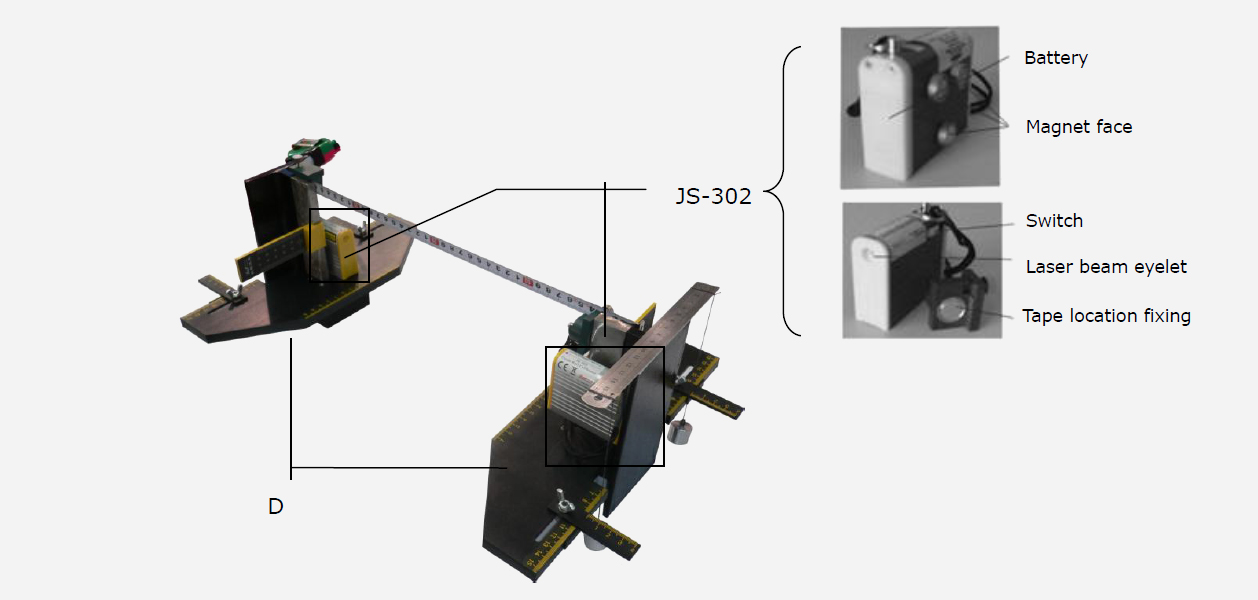

This instrument is composed by a pair of DW Set Rule, two pieces of JS-302 Laser Calibrator and the fixing block to fasten the steel tape. See P-1.

Technical parameters

| Wave length | 650nm |

| Laser power | ≤1mw (Laser class 2) |

| Tolerance of parallelism between beam and object | 1/2000 |

| Batterie | DC 3V AAA 5 |

| Lebensdauer der Batterie | 15h constant |

| Operation temperature | 0°C~50°C |

Function

DW Set Rule is mainly used to locate the guide rail’s position in X.Y direction according to the datum line while installation. JS-302 is mainly used for testing the co-planarity and measuring the deviation of guide rails.

The fixing block is used to fasten the steel tape to measure the distance. One person can carry out the measurement of distance between guide rails (DBG).

Operation

1. The method of guide rail installation

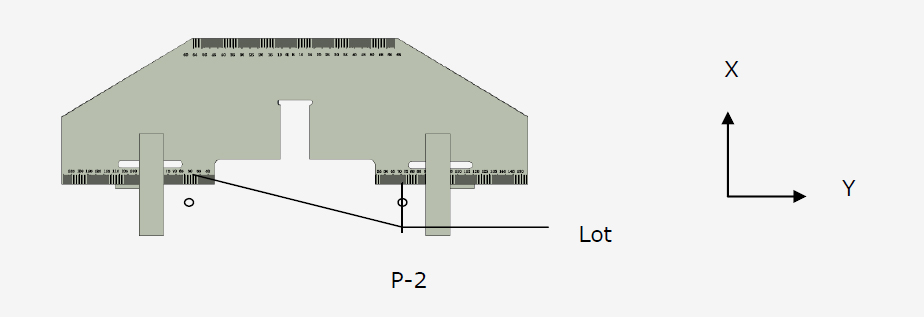

Find the installation position of primary guide rail on the auxiliary frame and make two plumb lines on the sides of primary guide rail with correspond distance. Fix the two plumb lines when they are steady. See P- 2.

Fasten DW Set Rule to the primary guide rail and fasten the small ruler by hexagonal spanner. According to the position of the center of two plumb lines on the Set Rule to find the other position of the guide rails. Same operation for the other guide rail.

2. Single instrument operation

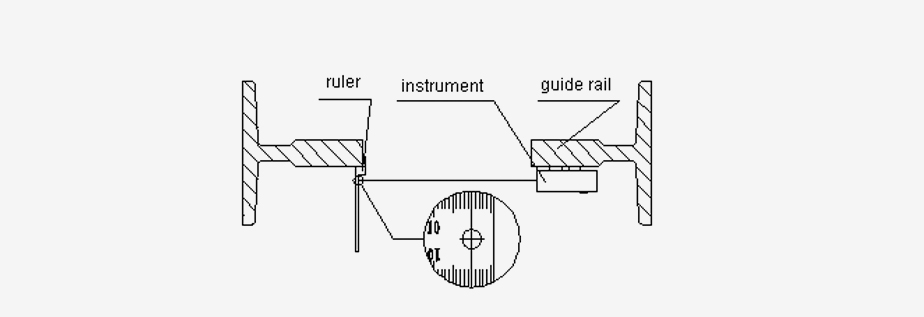

(1) Put the instrument closed to the side working face of guide rail and attracted by its magnet face. Put the magnetic ruler on the opposite guide rail (Re:P-3). Remark: the local faces of the instrument and ruler are in same direction. Turning on the switch lets the laser beam shooting out to the opposite rail. Adjust the position of ruler to let the spot on it. Adjust the guide rail to get the spot on”0”.

P-3

(2) Put another JS-302 instrument on the side working face of the other guide rail and let the laser beam shoot to the ruler on the opposite rail. Adjust the guide rails to get the spots on “0”(Re:P-4) and now the guide rails are co-planarity.

P-4

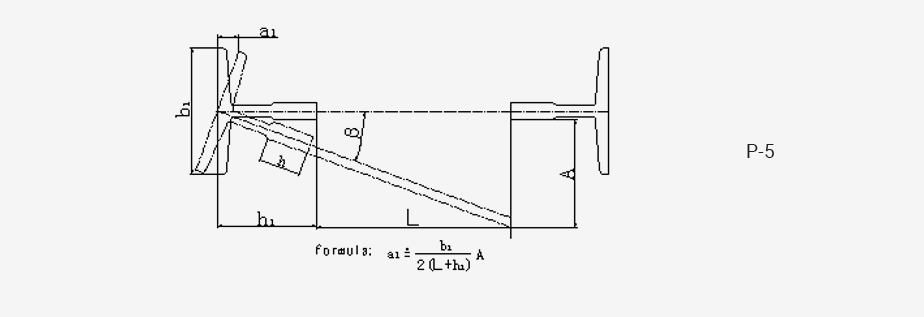

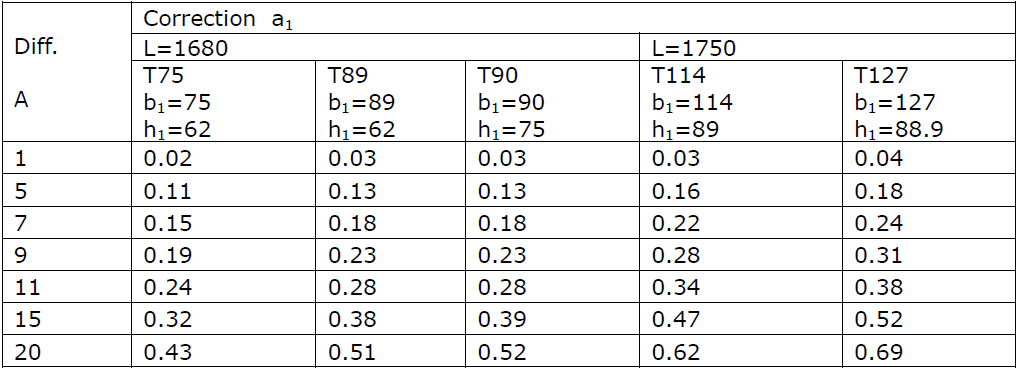

When the clip blot (or bracket) screwed, the co-planarity of two guide rail will be changed possibly. Correcting two guide rail’s deviation by adjusting bolt or changing the thickness of shim, the specific data can be calculated with the formula as follows:

Guide Rails Adjusting Example List

(All measures in mm)

3. Measuring the distance between two guide rails (DBG)

JS-302 has the fixing block. One of its functions is to prevent instrument against falling. The other of its functions is to fix the steel tape when measuring distance (Re: P-6).

Self-inspection and correction of the instrument

The magnitude of laser orientation deviation is very important for the co-planarity measurement of guide rails. So the functions of self-inspection and correction are offered as following:

1. Self-inspection

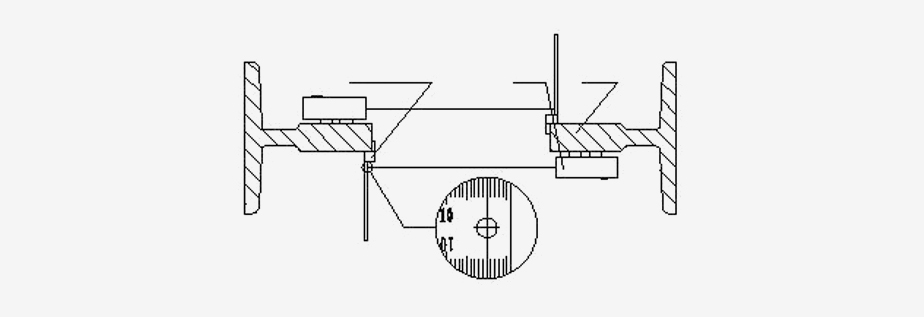

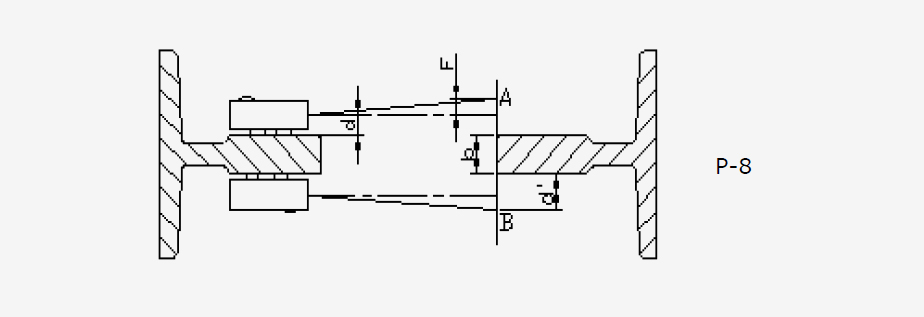

Attract the instrument on the two sides of the same point of guide rails which are parallel and no wearing. Mark the distance AB between two spots .If the thickness of the rail top face is b and central height of the laser beam is d(the distance between laser beam and positional face).Usually d=15.90mm.

Deviation F of the instrument is Deviation d’ is:

The deviation is 0 (F=0), when AB=b+2d is fulfilled.

F = [AB-(b+2d)]/2

d′= (AB-b)/2 = F+d

2. Correction:

(All examples in mm)

Important: The value F also depends from the distance between guide rails (DBG). Thus, F needs to be calculated new when working on a new DBG.

CE-Certification

Der Rail-Master DJ-A ist certified according to CE.

Warning

The laser beam is classified to class 2. Safety precautions are not necessary for the work. On a laser according class 2, a short sight into the laser beam doesn’t cause any injury. Nevertheless a sight into the laser beam should be avoided and if occasion arises the eyes shall to be closed immediately.